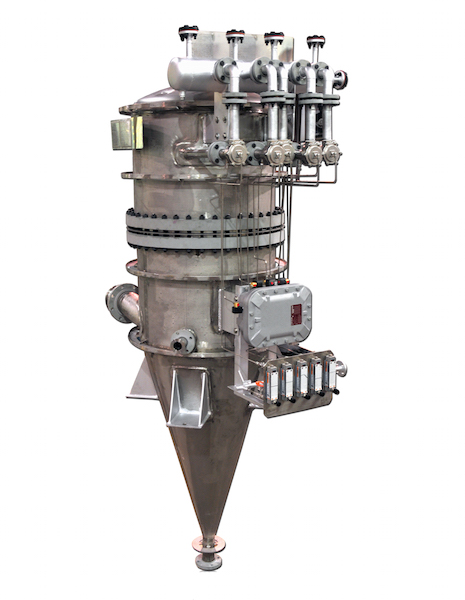

ASME Stainless Steel Pressure Vessels

Our perfectly crafted vessels perform under pressure.

ASME Stainless Steel Pressure Vessels. Built to Code. Built to Perform.

We were brought up with the simple belief that if you’re going to put your name on something, it better be right. It’s this mentality that pushes us to achieve the highest level of quality and design for any product that bears our nameplate—and it's why all the ASME stainless steel pressure vessels that leave our facility proudly bear our name.

Our vessels have limitless capabilities.

No matter which industry you serve—Chemical, Dairy, Pharmaceutical, and others—and no matter what your sizing requirements, we have the right team to assemble whatever style and design you have in mind:

- An ASME mixer tank

- Vertical or horizontal units

- Quick-access, open-top designs

- Square bodied units

- Tulip design vessels

- And much more.

There isn’t much we haven’t seen in our decades of building and fabricating some of the finest stainless steel pressure vessel equipment in your industry.

Size and Materials of Construction

We craft ASME vessels from 6" diameter up to 144" diameter and test each and every vessel to meet stainless steel ASME code requirements. We are capable of construction using almost any 300 Series Stainless Steel material as well as most High Nickel Alloys.

Whether your process demands an ASME mixer tank, bioreactor, or any of our other ASME stainless steel pressure vessels, our available surface finish regimen covers a broad range. From Mill plate to Standard Grit finish offerings, all the way to low mechanical 5Ra to 10Ra range, all our surface finishes can be complemented by our in-house H-Electropolish™ service.

Our ASME Stamps

HOLLOWAY AMERICA holds both ASME “U” and National Board “R” stamps. Below are a few of the stainless steel ASME codes and standards we meet:

- ASME Section VIII, Division I “U”

- ASME BPE

- CE / PED (Conformité Européenne, meaning "European Conformity”) / Pressure Equipment Directive

- CRN (Canadian Registration Number)

- NR-13

- MOM (Ministry of Manpower)

All welders at HOLLOWAY AMERICA are certified to ASME Section IX.

Ready to have a conversation about your project?

So are we. Talk to one of our representatives to get started.

Talk to a RepASME Pressure Vessel Materials

To ensure the ASME pressure vessels we engineer perform to perfection and are built to last, we use only excellent stainless materials:

- T–316L (standard)

- T–304L

- T–317L

- C–22

- C-276/HASTELLOY®*

- AL-6XN®*

- Other materials available by request

*HASTELLOY® is a trademark of Hanes International, Inc. and AL-6XN® is a trademark of Allegheny Ludlum.