Build. Store. Generate. All to your rigorous standards.

At HOLLOWAY AMERICA, our fabricators craft fuel storage tanks, chemical holding vessels, structural elements, and other ASME-rated equipment for the efficient, future-forward energy production you—and millions of others—rely on.

Our At-a-Glance Energy Industry Capabilities

While our expert craftsmen at HOLLOWAY AMERICA proudly build custom-engineered, ASME-rated pressure vessels and tanks to suit one or multiple needs, our energy equipment varies for niche processes:

- Structural steel fabrication

- Fuel storage tanks and holding tanks for oil and gas

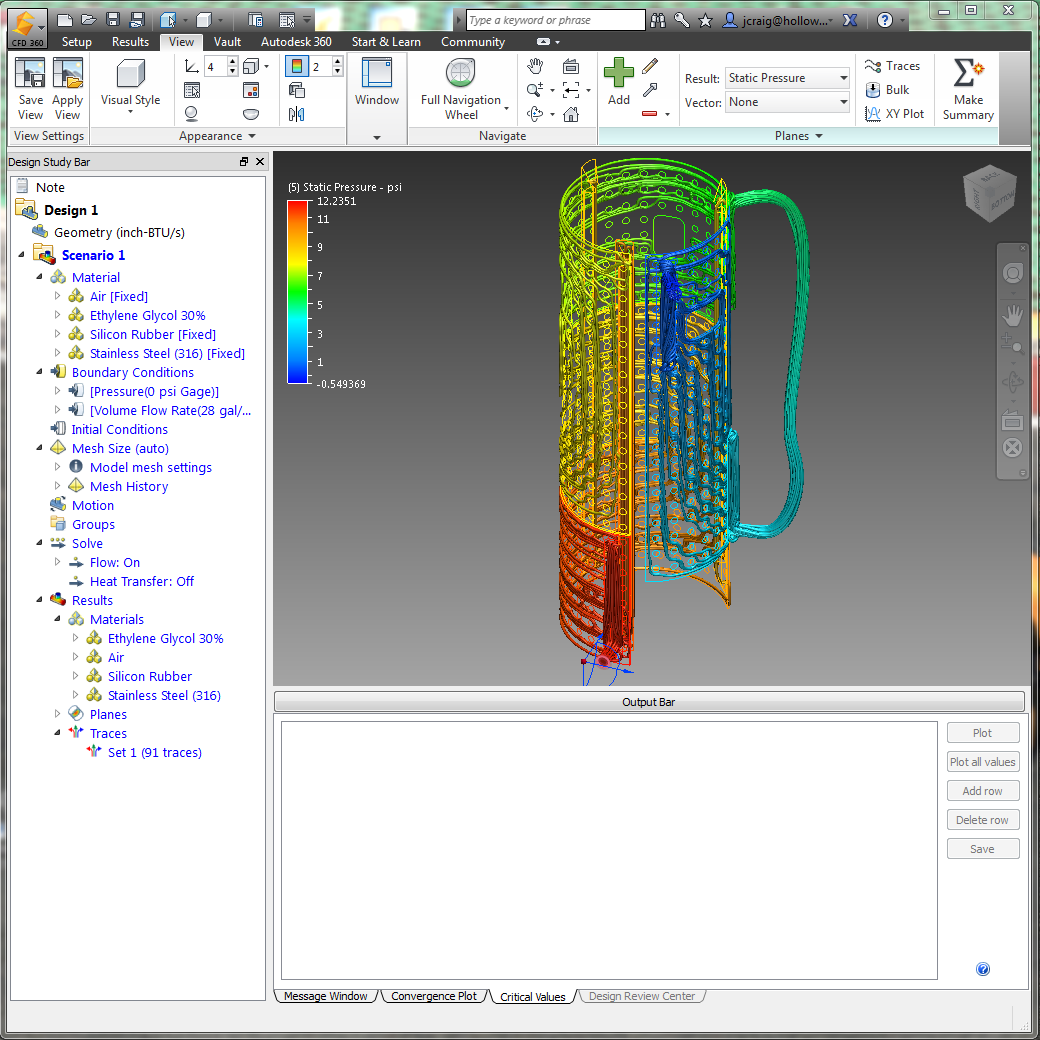

- Heat transfer equipment

- Energy saving and recovery equipment

- ASME-rated pressure vessels

- Processing tanks

- Mixing tanks

- Recovery tanks

- Smart tanks and vessels, like The intelliVessel™