Electropolishing

To ensure electropolished stainless steel that exceeds your expectations, we employ only experienced polishers.

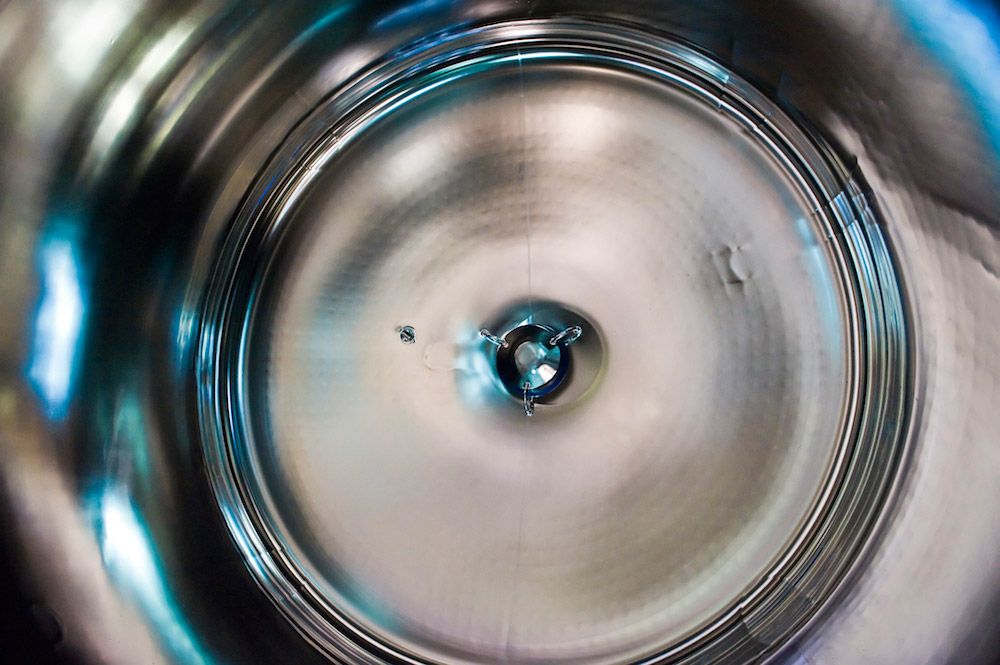

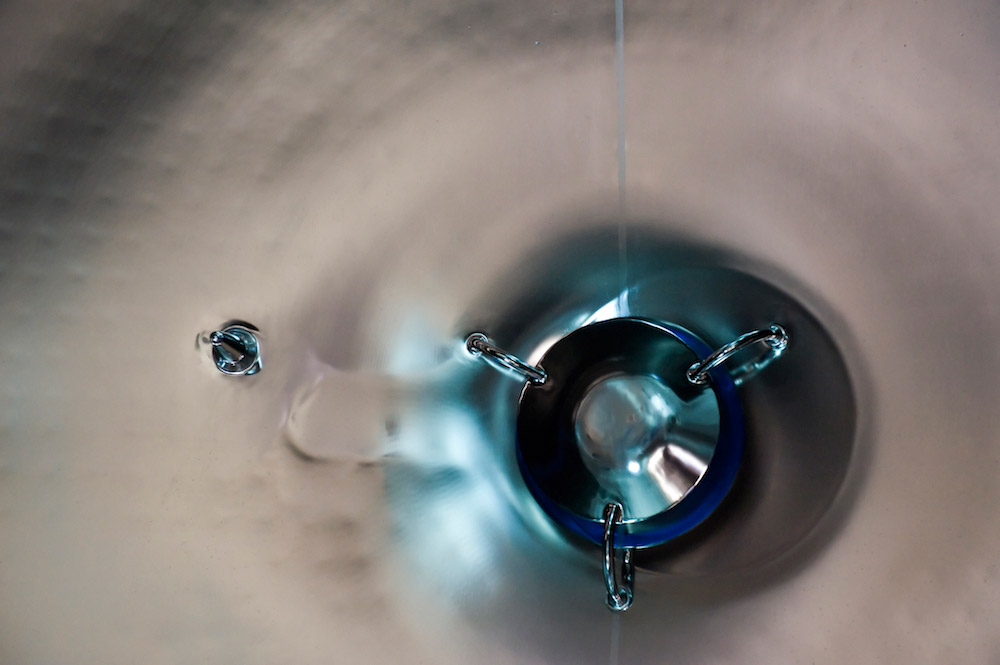

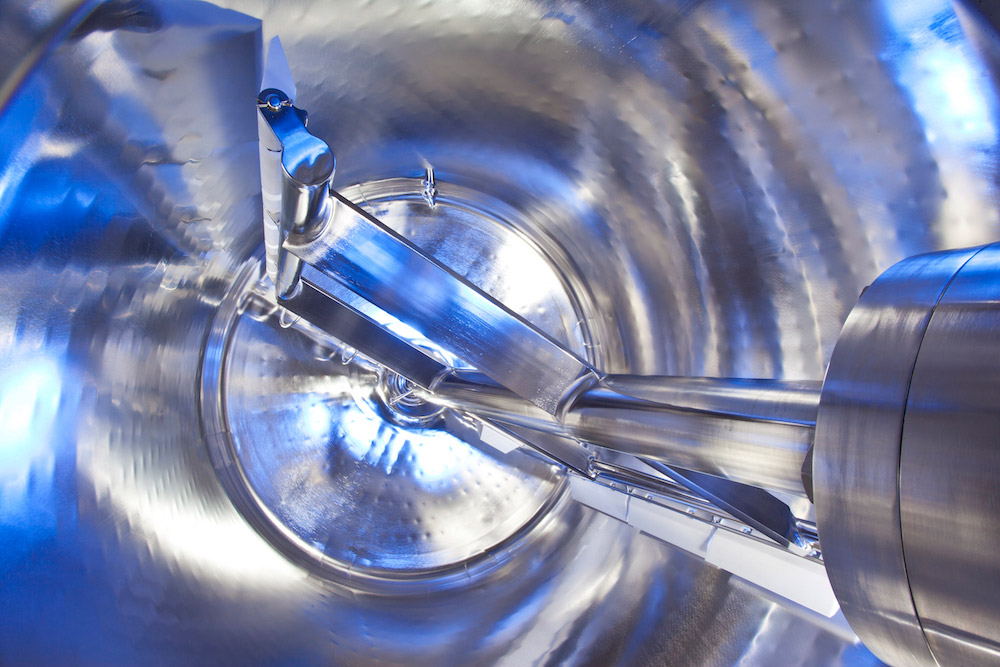

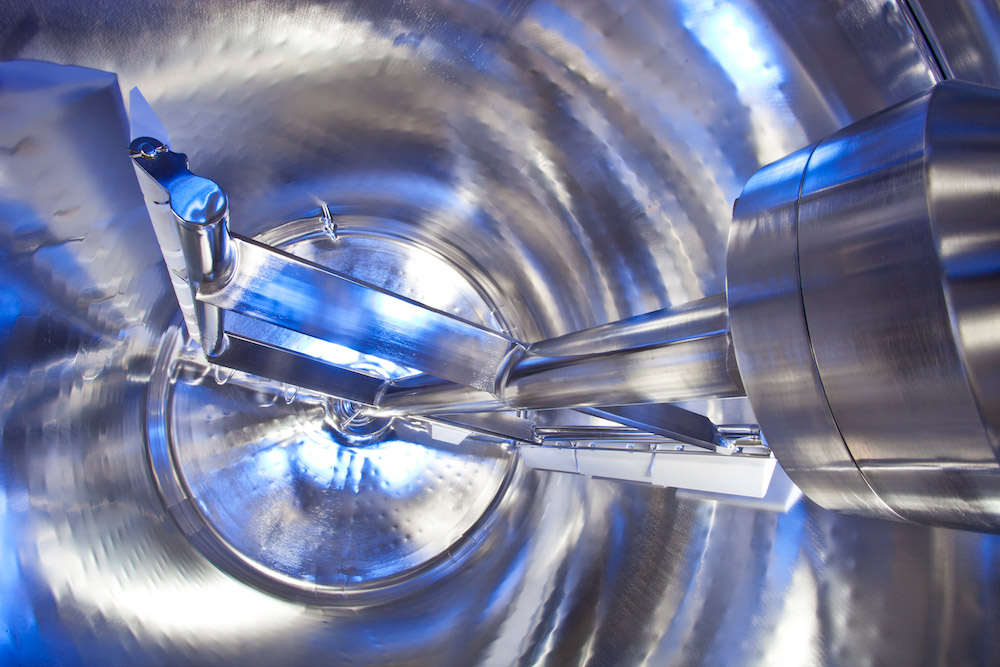

Electropolished Stainless Steel for a Uniform Vessel Surface & Luster

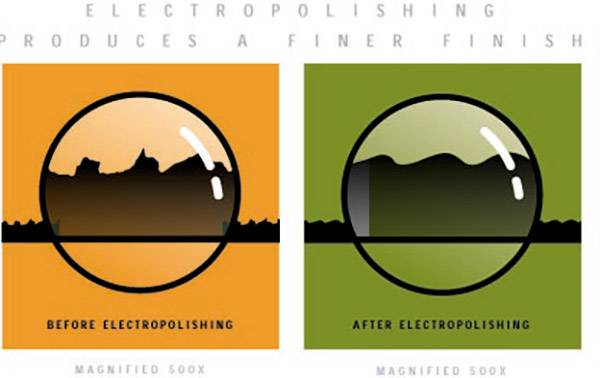

Electropolishing is a process of smoothing, polishing, and deburring metal surfaces in an electrolytic bath. This process selectively removes high points on the metal surface while producing a uniform high luster on the metal surface.

The process is essentially the reverse of electroplating. In a plating system, metal ions are deposited from the solution onto the work piece. However, an electropolishing system removes metal from the piece and adds metal ions to the solution. In the course of electropolishing, the tank is manipulated to control the amount of metal removal so that polishing is accomplished and, at the same time, dimensional tolerances are maintained. The result is an overall reduction of the surface profile with a simultaneous smoothing and brightening of the metal surface. The surface is easier to clean and sanitize . . . a quality that’s an absolute must in many industries such as BioPharm, Food, Dairy, Beverage, Nutraceutical, and Cosmetic.

HOLLOWAY’s Electropolishing System can Electropolish vessels from as small as a 3/8” tube to a 60,000 Liter Vessel. Electropolishing on 300 Series stainless to exotic alloys is available, and is our specialty.

How Electropolishing of Stainless Steel Works

Electropolishing of stainless steel pressure vessels and parts is an intricate process. A metal part is immersed in a liquid media and subjected to direct current. The metal part is made anodic (+) and a metal, usually copper, is made cathodic (-). The direct current flows from the anode to the cathode removing metal ions at a controlled rate. The amount of metal removed is dependent upon the specific bath, the temperature, speed, and the particular alloy being electropolished.

Unlike conventional mechanical finishing, this process does not smear, bend, stress or fracture the crystalline metal surface to achieve smoothness or luster. Instead, electropolishing removes metal from the surface producing a unidirectional pattern that is stress and occlusion free, smooth, and often highly reflective. Improved corrosion resistance is also a positive feature.

Features and Benefits of Electropolished Stainless Steel

Electropolished stainless steel pressure vessels and parts offer clear benefits:

- Surface brightening

- Burr removal

- Total passivation

- Oxide and tarnish removal

- Reduction in surface profile

- Removal of surface occlusions

- Increased corrosion resistance

- Removal of directional lines

- Reduction of surface friction

- Relief of surface stress

- Removal of hydrogen